In the biomedical sector, 3D printing has played a crucial role as an innovative technology for tissue engineering, organ fabrication, regenerative medicine, and drug delivery ( Figure 1). In recent years, additive manufacturing (AM), also called 3D printing, has emerged as a versatile technique and a valuable alternative to traditional manufacturing for the fabrication of complex materials through a layer-by-layer approach, thus resulting in new types of biomedical equipment, scaffolds, wearable devices, soft robotics, actuators, and flexible electronics. However, smart materials have become increasingly complex (in terms of structures, nano- and micro-topology, physical-chemical and mechanical features), outpacing traditional manufacturing due to the intrinsic mechanical and control limitations of these machines. The design and experimentation of smart structures has pushed researchers to develop different strategies in terms of behavior enhancement and property in relationship to specific applications. In addition, they are able to perform living-like functions such as self-healing, self-assembly, shape memory, self-evolving, sensing, and actuating. Usually, such materials respond to stimuli such as temperature, pH, humidity, light, electromagnetism, ion concentration, and mechanical force.

Smart materials, also called intelligent or responsive materials, are designed materials that have the ability to dynamically respond to external stimuli, adapting their features and functions for a specific need of applications. Lastly, an outlook on 5D printing is given as an advanced future technique, in which AI will assume the role of the fifth dimension to empower the effectiveness of 3D and 4D printing for developing intelligent systems in the biomedical sector and beyond. Then will be discussed the recent progress in AI-empowered 3D and 4D printing with open-loop and closed-loop methods, in particular regarding shape-morphing 4D-responsive materials, printing on moving targets, and surgical robots for in situ printing. In this review, an overview of 4D printing as a fascinating tool for designing advanced smart materials is provided.

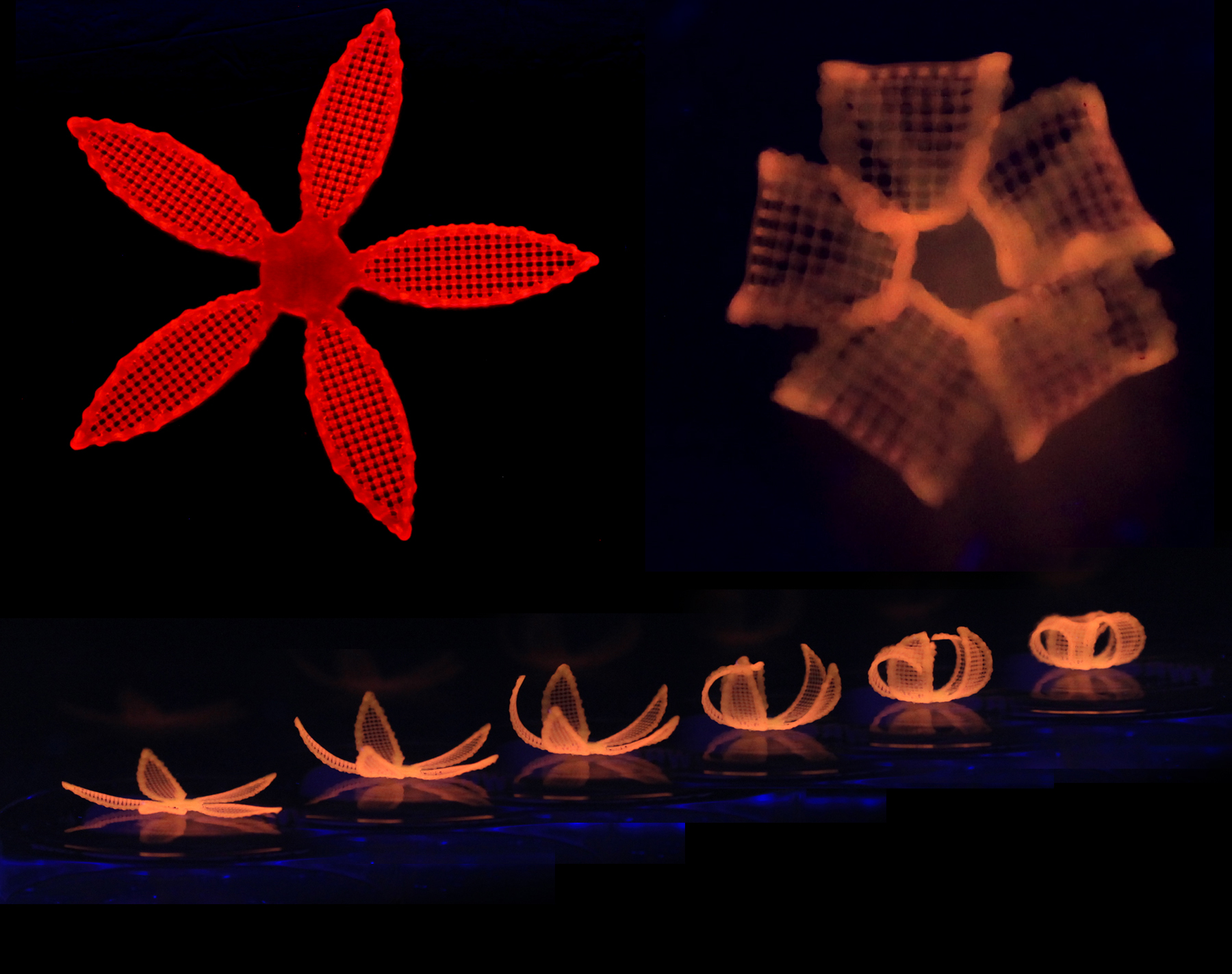

The rise of artificial intelligence (AI) could push these technologies forward enlarging their applicability, boosting the design space of smart materials by selecting promising ones with desired architectures, properties, and functions, reducing the time to manufacturing, and allowing the in situ printing directly on target surfaces achieving high-fidelity of human body micro-structures. Despite these potentials, 4D printed dynamic materials are still in their infancy of development. By preprogramming smart materials, 4D printing is able to manufacture structures that dynamically respond to external stimuli. The emergence of 4D printing addresses some of these drawbacks, opening an attractive path for the biomedical sector. These materials are fabricated ex situ, which involves first printing on a planar substrate and then deploying it to the target surface, thus resulting in a possible mismatch between the printed part and the target surfaces. However, biomedical materials used for 3D printing are usually static and unable to dynamically respond or transform within the internal environment of the body. In the last decades, 3D printing has played a crucial role as an innovative technology for tissue and organ fabrication, patient-specific orthoses, drug delivery, and surgical planning.

0 kommentar(er)

0 kommentar(er)